Engineering

We're putting all our efforts to ensure you'll get the highest quality and the best performances buying our forged or cast rims. Our know-how is based on 50 years of experience and on a constant feedback between our customers and our engineers.

Wheel centres

Cast centres

Cast centres come from a French aluminium foundry and are used for our historic wheels. We get them raw and have to machine them following the specifications of each order, sand and paint them with great care so that each wheel gets a stunning and unique look.

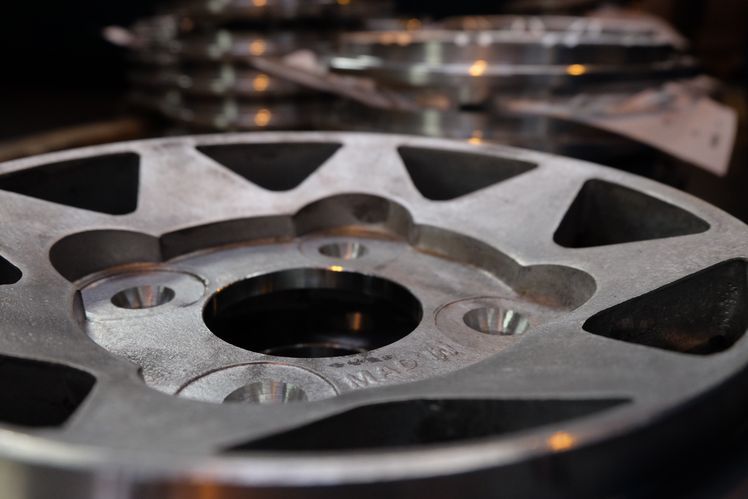

Forged centres

Our forged wheels are machined in raw forged aluminium blocks. Such forging process is among other used in high-quality mecanic parts in the aviation and space industry. Under a gigantic pressure of up to 8000 tons, the aluminium bloc is pre-heated to 500°C and pre-formed into a raw wheel centre. The alloy we use for our rims is the 6082 T6, which combines a high resistance degree and lightweight. Hence, a forged wheel is 20% lighter than a cast wheel. Forged wheels have the highest material density possible, which allows the wheel centre to be thinner.

The blocks are then machined by our technicians according to your needs and the design you wish. For example, we can adjust the design to fit big brake calipers or to perfectly fill the space within your wheel arches.

Lips and barrels

The material used for our lips and barrels is aluminium or stainless steel. We get our aluminium delivered in the form of 6 or 8mm thick discs, and ou stainless steel in the form of 2mm discs. Their quality is tested at each delivery. The raw materials are chosen because of their capacity to be spun precisely, while keeping great robustness and lightweight once mounted on your vehicle. The diversity of sizes we have on our lips and barrels allows for adjusting the width of your wheel with half-inch accuracy.

Metal spinning

Metal spinning is an old technique which principle is easy but requires a certain know-how to be executed with precision. A raw flat disc is positionned on a mandrel with the profile of the piece to be formed. The whole is the spun at a speed adapted to the material.

Roller tools exert a force over the material that flows over the block. During this phase, the metal undergoes very high compression, that gives it maximum resistance for a minimum weight. Finishing touches are then made by cutting tools to ensure perfect roundness.

This process is also called flow-forming and has been used to produce Formula One wheels, among others by OZ.

Turning

Turning is the second step in the production of lips and barrels. The spun elements are put on a lathe. Our technicians are then applying precise finishing d’une haute précision.

Piercing

Cette étape consiste à percer de façon la plus précise possible, tous les trous qui vont permettre l’assemblage des voiles à la partie centrale. Nous effectuons cette opération sur des machines à commande numérique, garantissant ainsi une précision absolue, et nous donnant la possibilité d’adapter les voiles à toutes les demandes.

Polishing

Polishing is made in two steps. A first polish eliminates any imperfection and gives a smooth aspect to the metal. The second polish is a special process that gives the metal a shiny look.

Finallly, each serie is finely controlled to ensure that none of our products has lateral or radial run-out.

Before being send out to our customers, each wheel is checked to ensure it has perfect roundness and that its finish is flawless.